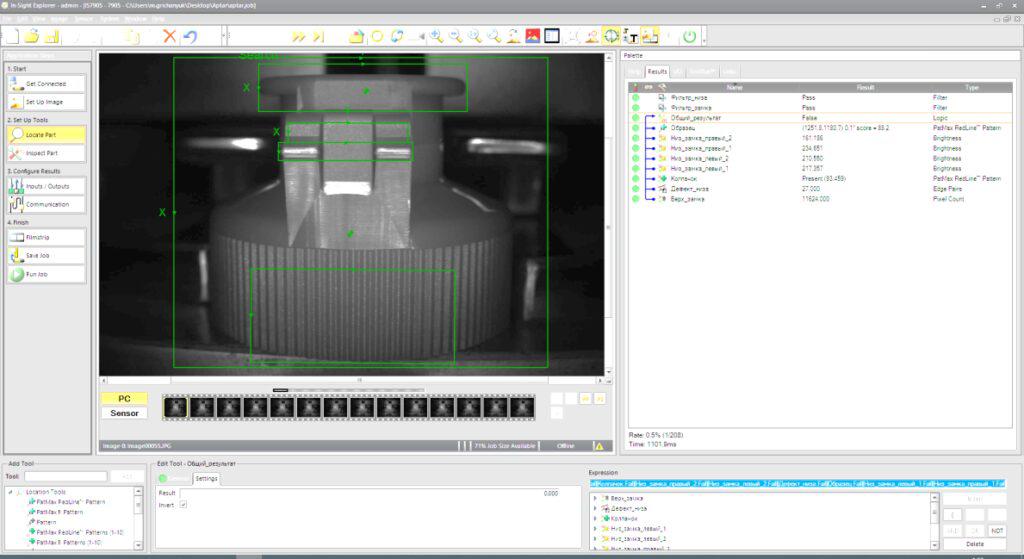

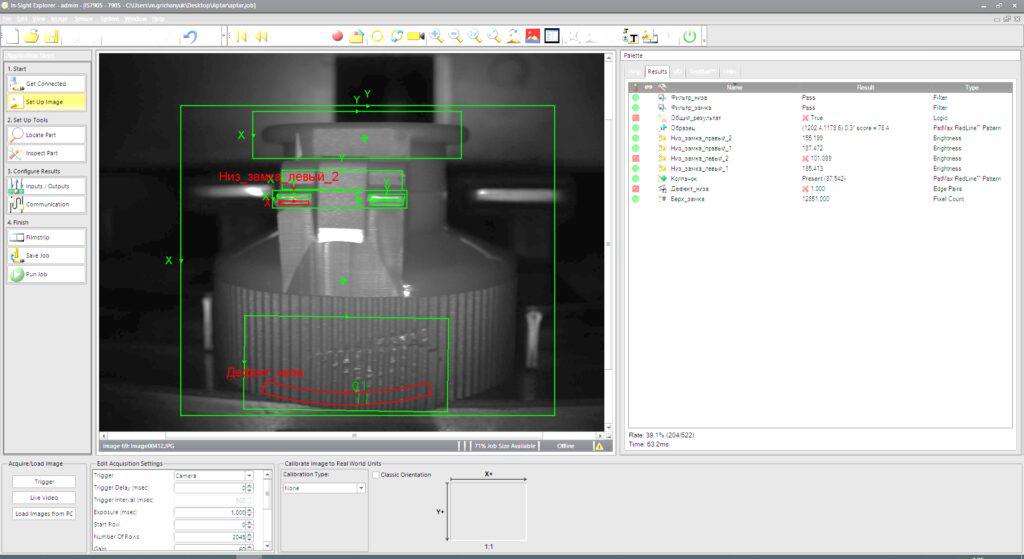

Plastic cap inspection system

The plastic cap inspection system (PCIS) is designed to detect defects in plastic caps and subsequently transmit a rejection signal.

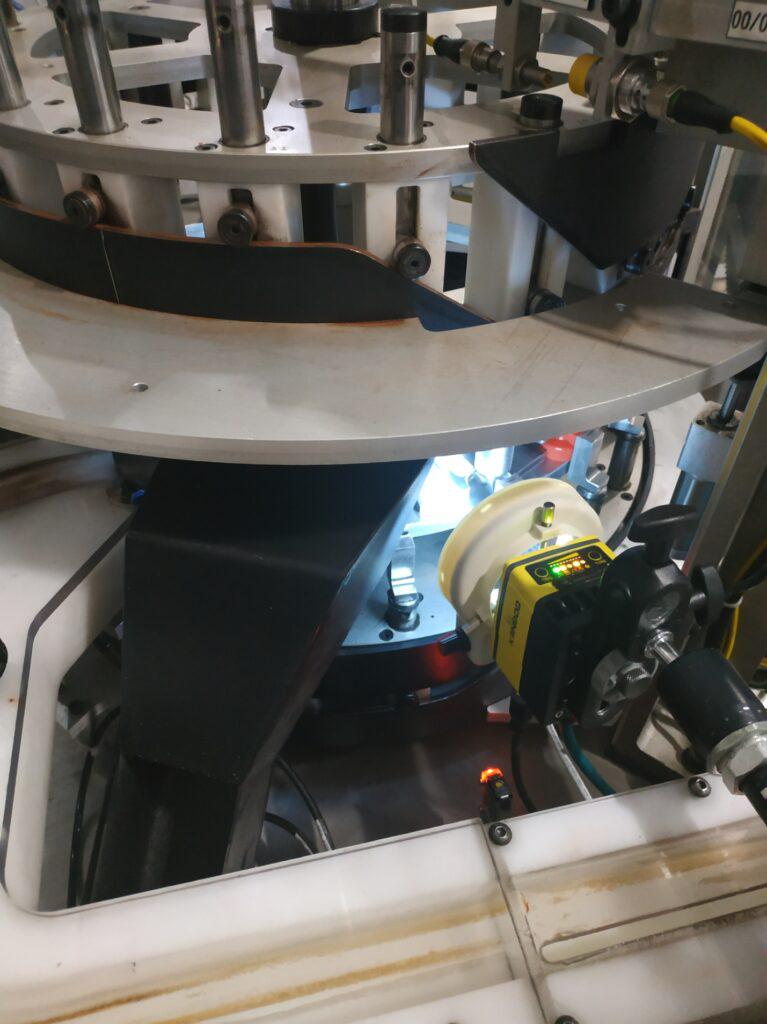

The PCIS is installed directly on production equipment to ensure the highest efficiency and productivity.

Common defects of plastic caps: scores, creases, burrs, cracks, scratches, foreign particles, etc.

PCIS productivity: 7 caps per second.

Minimum detectable defect size: 0.5 mm.

When a defect is detected, the PCIS generates a digital signal to reject the defective cap with a defective seal.

Write to us