Print inspection* system

The print inspection* system (hereinafter referred to as PIS) is designed to detect printed character defects on both sides of a plastic product (top and sides).

Minimum defect size = 1.0 mm.

The duration of one PIS inspection cycle = not more than 1.0 seconds.

To implement inspection from both sides, two machine vision cameras and special dome lights shall be installed to provide a clear and glare-free image of the item under inspection.

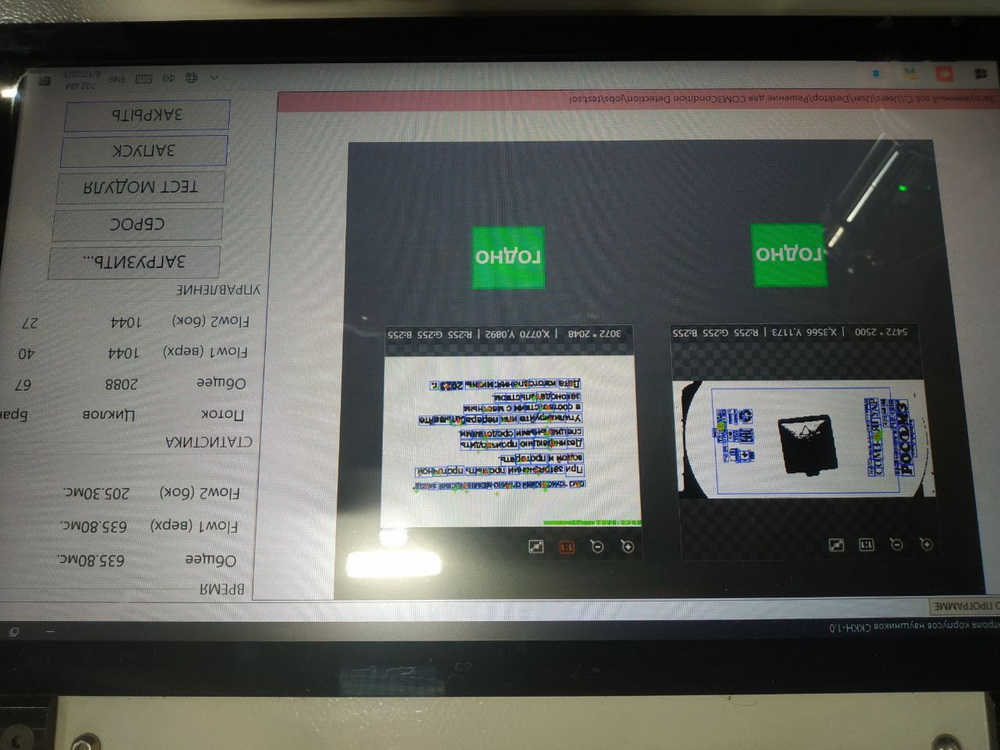

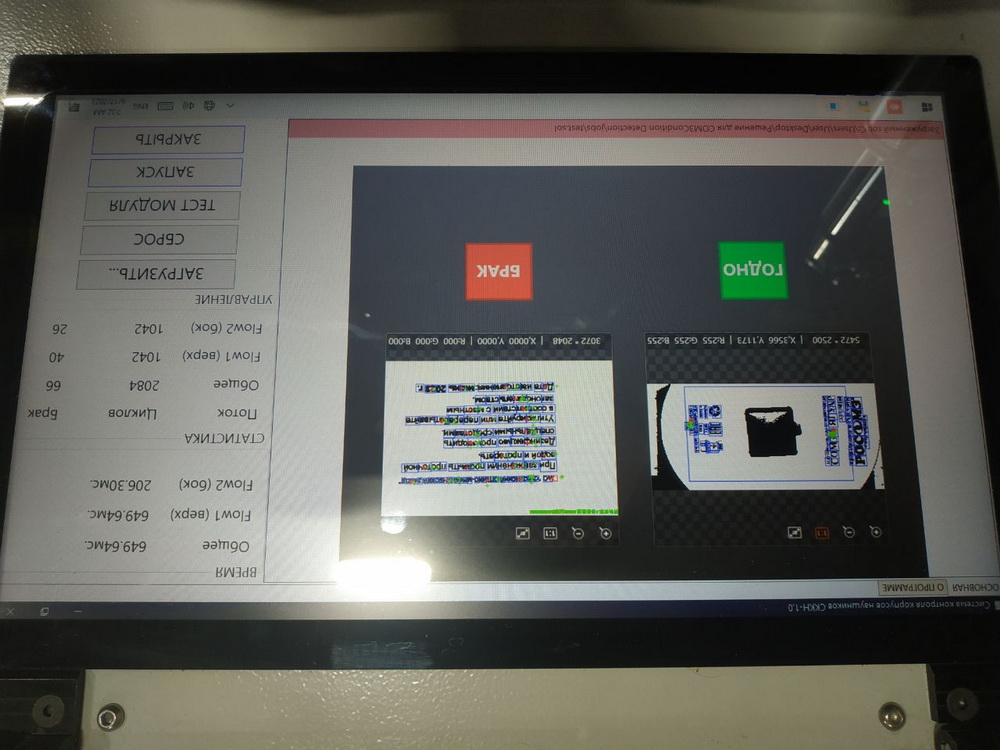

To enable prompt viewing of print inspection results, a graphical operator interface has been developed.

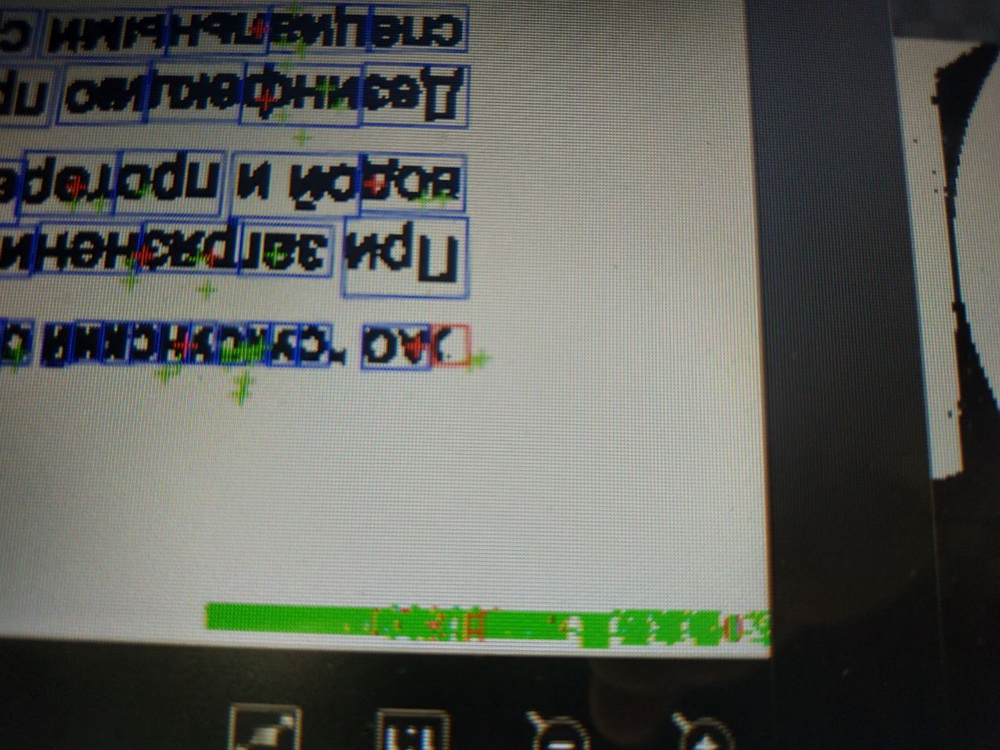

If no defects are detected, PASS (ГОДНО) is displayed under the image of each type; if a defect is detected, FAIL (БРАК) is displayed.

The defect detected by the PIS is highlighted with a red box.

The inspection statistics are also displayed on the operator panel. The inspection result is transmitted through the PIS digital output to the conveyor control system.